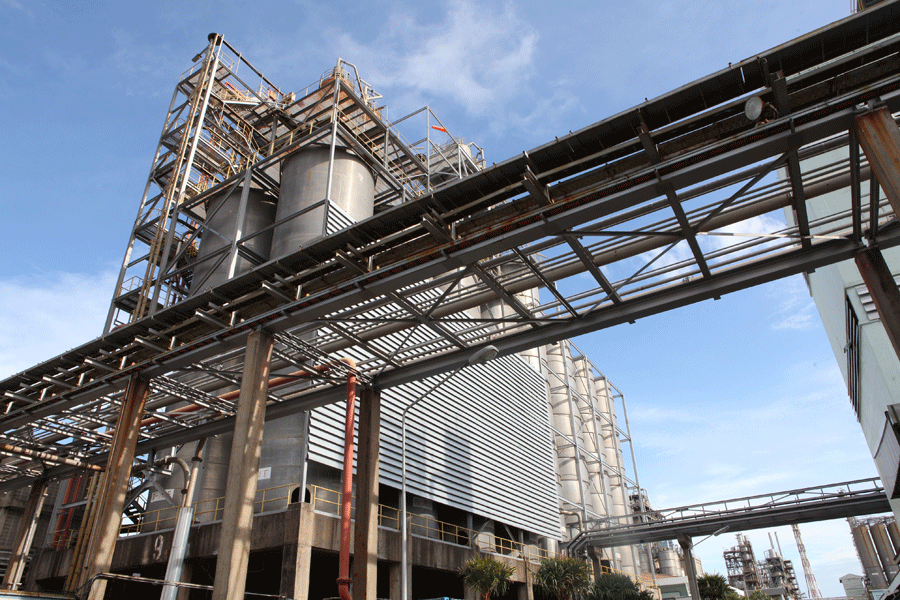

Established in 1978, the company is the first manufacturer of LDPE plastics resins based in Thailand and has become the country’s only EVA manufacturer with a total annual production capacity of 158,000 tons. Supplying both domestic and foreign markets, the company provides a wide range of resins for use in the production of packaging, containers, lamination, shoes, toys and hot melt adhesive.

|

Plastic Resin of TPIPL |

TPI Polene produces many types of plastic resins. Plastic resins under “POLENE” trademark are polyolefin products including Low Density Polyethylene (LDPE) and Ethylene Vinyl Acetate (EVA) that serve various kinds of applications e.g. consumer and industrial packaging, automotive and electrical parts, toys, agricultural equipments, wire and cable insulation, footwear, hot melt adhesive application, etc.

|

Low Density Polyethylene |

Low Density Polyethylene of LDPE is a type of polyolefin resins widely used for consumer product. “POLENE” LDPE has been classified to 4 grades for different application.

|

POLENE? D2022, D2024 |

-Heavy Duty Grade-

LDPE grades having unique properties of very low Melt Flow Index (0.2 to 0.75 g/10min) are practical for heavy duty applications e.g. ice bag, shrink film, stretch film, agricultural film, cosmetic tube, etc.

|

POLENE? J4324, JJ4324 |

-Film Grade-

LDPE grades having additional additive “Antiblocking and Slipping Agent” to improve film properties are applied to various film and injection applications e.g. multi-purpose bag, bottle cap, etc.

|

POLENE? MM1018 |

-Lamination Grade-

LDPE grades used for lamination works serving thinner film and clarity.

|

POLENE? S1018 ST1018 SU1018 SSS1018 |

-Injection Grade-

LDPE grades having high MFI (20 to 45) are proper for injection molding e.g. toys, bottle cap, container, etc.

Phone number: (66 2) 213-1039 Ext. 12072